3D Printing is for so much more than just making brightly colored plastic pieces of crap

Author: Scott Hanselman

When you first start learning about 3D Printing you’ll usually find yourself looking at a bunch of brightly colored plastic busts. The first 3D printed thing I ever saw was a florescent green Yoda head. First you’re like “HOW DID YOU DO THIS?” but quickly you’re more like “OK, how many brightly colored plastic pieces of crap do I really need in my life?”

I thought a 3D Printer was a $2000 thing, and of course, that’s a heck of a lot of money. But I wanted to get into 3D Printing because I’d started to talk to some more advanced folks locally here in Portland and they assured me that it was cheaper than I thought and more useful than I thought. I got a $599 Printrbot Simple Metal from Amazon. You can also get a kit and assemble it yourself for $539 but the assembling is kind of hard work.

I’ve learned three things. They are perhaps obvious to you, but they have been amazing for me and my sons as we learn more about 3D Printing.

LESSON 1 – YOU CAN UPGRADE YOUR 3D PRINTER

There’s a great website called Thingiverse that is filled with models that others have made or remixed. You can join in and just download, or, ideally, create your own models and share. I’ve used Tinkercad with the kids to create new models.

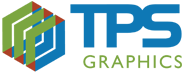

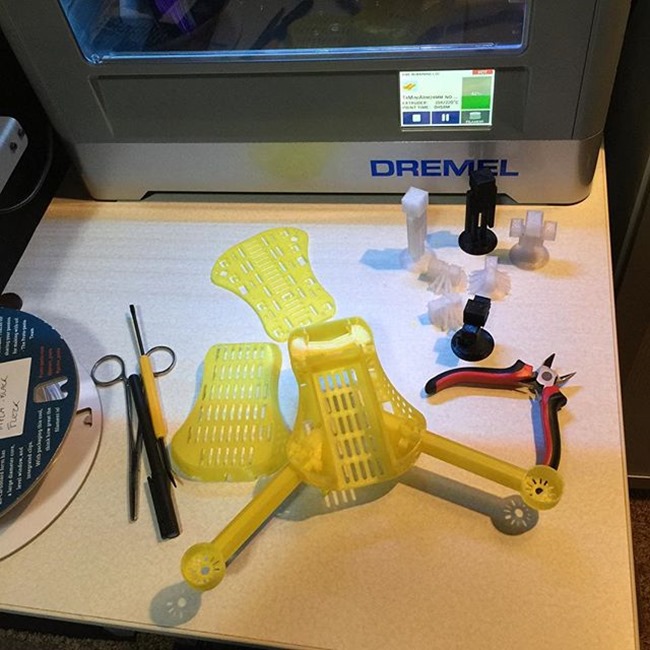

One of the great jokes in 3D Printing is that people with printers never print anything useful, they just print upgrades to their printers. When you are getting started, this is actually kind of true. I took my PrinterBot and printed a base, a spool holder (figuring out where to safely and reliably hang the spools of plastic filament is a big problem.

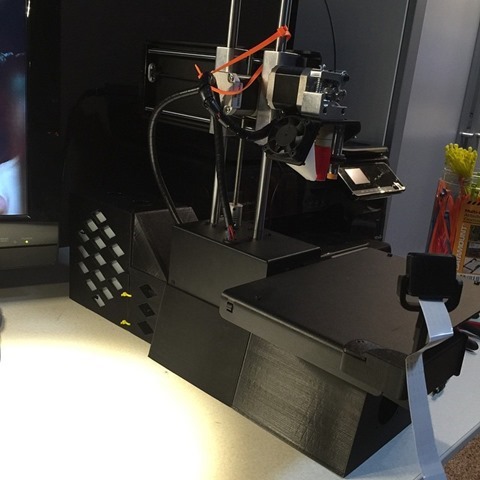

NOTE: You can also upgrade the Nozzle in your printer. Later I’ll talk about “exotic” filaments that can give amazing results but are also more abrasive and can wear out the stock nozzles that come with your printer. I upgraded the nozzle on my Dremel for just $14.99 using this Brass Nozzle from Proto-Pasta and was able to make the swap and get back to printing in about 20 minutes, not counting the feeling of accomplishment.

LESSON 2 – THERE ARE “EXOTIC” PLASTIC FILAMENTS THAT ARE GAME CHANGERS

There’s a local small business just over the river in Vancouver, Washington called “Proto-Pasta.” They a company of just three people that started as a Kickstarter two years ago. They sell “exotic” plastic filaments that have additives and properties that take your prints out of the “bright plastic crap” category and into something more interesting.

They have a filament with added Carbon Fiber that has created some of the smoothest and most amazing prints I’ve ever made. It doesn’t gain strength with this addition, but rather rigidity. They have a Stainless Steel filament that is great for making jewelry or robots or anything that you want to have the heft and feel of steel. They’ve even got a filament with Iron so your prints can react to magnets.

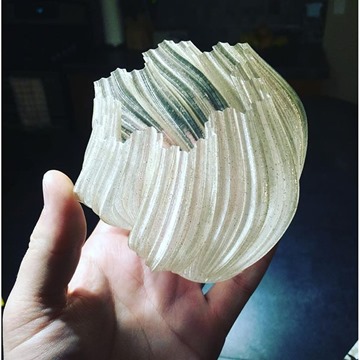

I’ve used their High-Temperature filament that starts out clear but you bake it (literally, in your oven) afterwards and it’ll shrink slightly and get VERY hard and turn opaque.

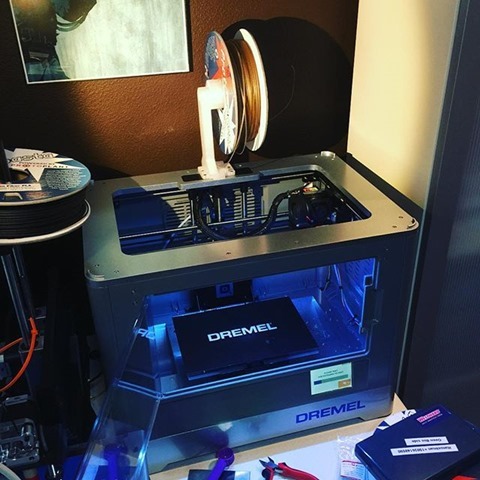

More recently I’ve been trying a filament with added Pine (yes, wood) that not only smells great but looks amazing with wood flecks inside the filament.

I’ve made dishes, vases, pieces of art for shelves, and geometric shapes for gifts this Christmas. Each one is VERTY different just by changing the filament. It’s been more than changing color. These exotics change the texture and weight, and by making small changes in the software you can make them thicker or, in my case, thinner and more translucent.

LESSON 3 – YOU CAN PRINT PARTS AND THEN ASSEMBLE THINGS USING BOLTS, GLUE, ETC.

This one may be obvious, but you don’t have to do everything with plastic. My 8 year old and I are slowly making a “T4 Quadcopter” designed by Brendan from New Zealand (a reader of this blog) and this project will require not only lots of printed pieces but assembled pieces. You can super glue, screw, bolt, zip-tie and snap 3D printed parts together. I’ve been surprised at how string these parts can be when they are combined. This quadcopter will be held together with small metric nuts and bolts and zip-ties as well as some very clever snaps built-in as part of the 3D Printed model.

We are having a blast with this family hobby. We’ve fixed things around the house, made art, explored material science, thought about geometry, and learned about how software and hardware work together to create something bigger. Are you getting into 3D Printing?

Source: www.hanselman.com/blog/3DPrintingisforsomuchmorethanjustmakingbrightlycoloredplasticpiecesofcrap.aspx.

We Can Be

Great Together

QUICK LINKS

610-692-1810

705 E. Union Street

West Chester, PA 19382

We Can Be Great Together

610-692-1810

QUICK LINKS

705 E. Union Street

West Chester, PA 19382